(770) 589-1605

BadAss Safety Striping: Command Your Warehouse Floor with Clarity, Compliance, and Unbeatable Durability

Taming the Chaos – Why Your Warehouse Floor Needs BadAss Striping

Walk into many warehouses or manufacturing plants, and you might see a scene of controlled chaos. Unmarked floors can lead to confusing traffic patterns, inefficient storage, potential safety hazards lurking around corners, and the constant worry of falling short of regulatory standards. Forklifts weave around pedestrians, valuable inventory gets misplaced, and critical safety equipment becomes obstructed. This isn't just inefficient; it's risky and potentially costly.

Now, picture that same space transformed. Clear, bright lines define walkways and traffic lanes. Designated zones mark storage areas, workstations, and hazardous equipment. Emergency exits and safety equipment are instantly identifiable. This is the power of professional safety striping and signage – it brings order, clarity, and control to your operational environment. It's not just about lines on a floor; it's about creating a visual language that enhances safety, boosts efficiency, and ensures compliance.

At BadAss Concrete Floors, we understand the critical role floor markings play in demanding industrial settings. We've installed millions of linear feet of safety striping across the Southeastern US, helping businesses like yours tame the chaos and command their workspace. As certified installers for leading manufacturers, we bring unparalleled expertise and commitment to every project, ensuring your facility operates at peak safety and efficiency.

What Exactly is Safety Striping and Safety Signage? (Beyond Just Lines on a Floor)

Safety Striping, often referred to as floor marking, involves the precise application of durable lines, shapes, symbols, and colored zones directly onto concrete floors within industrial, warehouse, manufacturing, and distribution environments. These markings serve as essential visual cues, guiding movement, defining spaces, and alerting personnel to specific conditions or requirements. While traditionally applied using paint, modern, high-performance solutions often utilize durable coating systems like epoxy or polyaspartics for superior longevity, especially on concrete.

Safety Signage works hand-in-hand with floor striping. This includes wall-mounted signs, floor-applied signs (often adhesive or embedded), and other visual aids that provide specific warnings, instructions, or identification. Think "Caution: Forklift Traffic" signs at intersections marked with floor lines, or signs identifying the type of PPE required in a specific striped zone. Together, safety striping and signage create a comprehensive visual communication system.

The Primary Goals of implementing a professional safety striping and signage system are multifaceted and crucial for operational success:

-

Enhance Workplace Safety: This is the paramount objective. Clear markings prevent accidents by physically separating pedestrian traffic from vehicle routes like forklift paths. They clearly identify hazardous zones around machinery or electrical panels, restricted areas, and potential physical hazards like low clearance or trip points. Markings also pinpoint the location of vital safety equipment, ensuring rapid access during emergencies.

-

Improve Organization & Efficiency: A well-marked floor is an organized floor. Striping defines specific areas for raw materials, work-in-progress (WIP), finished goods, pallet storage, tool placement, and waste disposal. It establishes clear work cells and staging lanes, optimizing workflow and minimizing the time wasted searching for items or navigating the facility. This systematic approach directly supports lean manufacturing principles like 5S.

-

Ensure Regulatory Compliance: The Occupational Safety and Health Administration (OSHA) mandates certain safety standards for workplaces. Proper floor markings are essential for meeting these requirements, particularly concerning clear aisles and passageways (OSHA 1910.176, 1910.22) and the use of specific colors for hazard identification (OSHA 1910.144). Adhering to these standards through professional marking helps facilities avoid costly violations and penalties.

Effectively, safety striping and signage move beyond mere decoration; they form a fundamental visual operating system for your facility, underpinning safety protocols, optimizing operational flow, and ensuring you meet critical regulatory obligations.

Unlock Peak Performance: The BadAss Benefits of Professional Floor Marking

Implementing a professionally designed and installed safety striping system from BadAss Concrete Floors delivers tangible benefits that directly impact your bottom line and operational integrity. It's not just about compliance; it's about creating a safer, smarter, and more productive workspace.

-

Dramatically Increase Workplace Safety: A clearly marked floor is inherently safer. By establishing distinct pathways for pedestrians and forklifts, you minimize the risk of collisions, a common source of serious injuries in warehouses. Designating hazardous zones around operating machinery, high-voltage electrical panels, or areas with potential fall or trip risks alerts employees to exercise caution. Marking restricted areas prevents unauthorized access, while clearly identifying the locations of fire extinguishers, eyewash stations, and first aid kits ensures immediate response capability in emergencies. Reducing accidents not only protects your workforce but also significantly cuts costs associated with injuries, such as medical expenses, workers' compensation claims, and lost productivity due to downtime.

-

Boost Efficiency & Conquer Chaos: Eliminate confusion and wasted movement with logical floor markings. Defining specific zones for inventory storage (raw materials, WIP, finished goods), pallet placement, tool storage, and equipment parking streamlines material handling and reduces the time employees spend searching for items or figuring out where to put them. Clear traffic lanes for forklifts and designated pedestrian walkways optimize movement throughout the facility, preventing bottlenecks and improving overall workflow. This enhanced organization directly supports efficiency methodologies like 5S, leading to measurable gains in productivity and throughput. An organized, efficient floor is also a safer floor, as clear pathways reduce clutter and potential hazards.

-

Nail OSHA Compliance (and Avoid Headaches): OSHA regulations aren't suggestions; they're requirements. Standard 1910.176 mandates that permanent aisles and passageways must be appropriately marked to ensure safe material handling and storage. Standard 1910.22 requires walking-working surfaces to be maintained in a safe condition, which includes clear access and egress. Standard 1910.144 specifies the use of red and yellow for marking certain physical hazards. Failing to meet these requirements can result in significant fines and citations during inspections. Professional safety striping ensures your facility adheres to these critical standards, demonstrating a commitment to safety and helping you avoid costly penalties.

Investing in professional safety striping is an investment in a safer, more efficient, and compliant operation. The benefits are interconnected – improved safety leads to better efficiency, and compliance underpins both.

Decoding the Lines: Common Warehouse Markings and Standard Colors

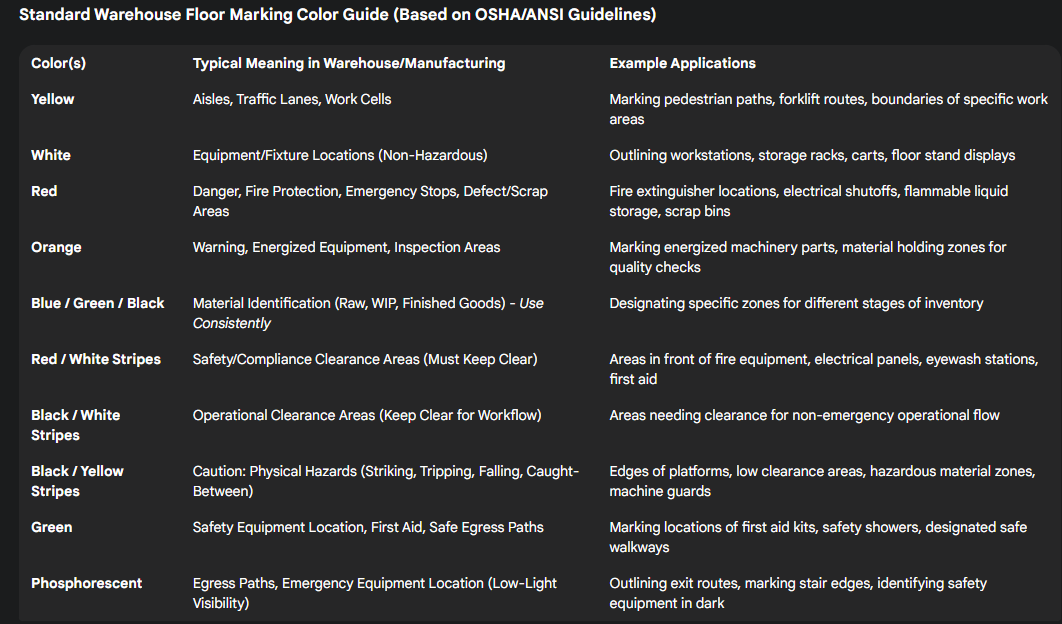

Understanding the "language" of floor markings is key to maximizing their effectiveness. While OSHA mandates marking for aisles and specific colors for hazards, the widely adopted ANSI Z535 standards provide a more comprehensive color-coding system that promotes universal understanding. Consistent use of these colors turns your floor into an intuitive guide. Here are common applications and their typical color associations:

-

Aisle Markings: Essential for directing traffic flow and separating pedestrians from vehicles.

-

Requirement: OSHA requires permanent aisles and passageways to be marked. Lines must be at least 2 inches wide (2-6 inches recommended). Aisles should be at least 4 feet wide, or 3 feet wider than the largest equipment used.

-

Common Color: Yellow is typically used for marking aisles, traffic lanes, and work cells.

-

-

Hazard Warnings: Alerting personnel to potential dangers.

-

Physical Hazards: Black & Yellow Diagonal Stripes indicate caution for physical hazards like striking against, stumbling, falling, tripping, "caught-in-between," low clearance, or edges. Often used around hazardous machinery or material areas.

-

Fire & Emergency Stops: Red identifies fire protection equipment (extinguishers, hydrants), danger areas, emergency stop buttons/bars on machinery, and containers for flammable liquids.

-

-

Designated Areas & Equipment: Organizing materials and equipment.

-

Equipment/Fixtures: White often marks locations for non-hazardous equipment like workstations, carts, racks, and floor stand displays.

-

Materials: Blue, Green, or Black are commonly used to designate areas for raw materials, work-in-progress (WIP), or finished goods. Consistency is key; choose one color system and stick to it.

-

Inspection/Energized Equipment: Orange typically marks material holding areas for inspection or designates energized equipment.

-

Defects/Scrap: Red is often used for defect, scrap, rework, or 5S red tag areas where items need evaluation.

-

-

Safety & Operational Clearance Zones: Ensuring access and preventing obstructions.

-

Safety Equipment Clearance: Red & White Stripes indicate areas that MUST be kept clear for safety/compliance reasons, such as access to electrical panels, firefighting equipment, eyewash stations, safety showers, and first aid stations.

-

Operational Clearance: Black & White Stripes mark areas to be kept clear for operational purposes (e.g., workflow, non-emergency access), not directly related to safety compliance.

-

-

Egress Pathways & Emergency Exits: Guiding personnel to safety during emergencies.

-

Requirement: Must be clearly marked and lead to exits.

-

Common Colors: Green often indicates safety equipment locations and safe pathways. Phosphorescent (Glow-in-the-Dark) tape or paint is crucial for visibility in low-light or power outage conditions.

-

Invest Smart, Save Big: The Long-Term ROI of BadAss Safety Striping

Think of professional safety striping not as an expense, but as a strategic investment that pays dividends over time. The upfront cost is often significantly outweighed by the cumulative savings generated through enhanced safety, improved efficiency, compliance assurance, and reduced long-term maintenance.

-

Slash Accident-Related Costs: Fewer slips, trips, falls, and collisions translate directly into financial savings. This includes reduced workers' compensation insurance premiums, lower medical expenses, minimized lost workdays, and avoidance of potential legal liabilities. Preventing impacts between forklifts, personnel, racking, and inventory also eliminates costs associated with equipment repairs, product damage, and operational downtime needed for cleanup or repairs. Polished or sealed concrete floors, often used with striping systems, can also reduce wear on forklift tires and components due to smoother surfaces and filled joints.

-

Boost Productivity & Throughput: Time is money in any operation. Clear visual cues from floor markings eliminate confusion and streamline movement. Workers spend less time navigating, searching for materials, or figuring out workflows. Optimized traffic flow for both pedestrians and vehicles prevents bottlenecks and delays. This increased operational efficiency directly translates to higher throughput and reduced labor costs per unit handled.

-

Dodge Compliance Penalties: Failing an OSHA inspection due to inadequate floor markings can result in substantial fines and mandatory corrective actions. Proactively implementing a compliant marking system is a cost-effective way to avoid these penalties and the associated administrative burden.

-

Protect Your Assets: Clearly marked storage zones, traffic lanes, and equipment areas help prevent accidental damage to valuable inventory, expensive machinery, and the building structure itself. Furthermore, using durable coatings for striping can help seal the concrete, reducing dust generation which can harm sensitive equipment and stored goods.

-

Reduced Maintenance & Reapplication Costs: Unlike temporary solutions like standard floor tape that can peel, fray, and require frequent replacement (sometimes within months in high-traffic areas), professionally applied durable coatings like epoxy or polyaspartics last for years. This dramatically reduces the recurring costs of materials and labor associated with re-striping. Coated lines are also typically easier to clean than tape or bare concrete, saving janitorial time and resources. Specialized application machinery can further reduce labor costs for large striping projects.

Considering the combined impact of preventing costly accidents, boosting daily efficiency, ensuring compliance, protecting assets, and minimizing long-term maintenance, the return on investment for high-quality, professionally installed safety striping becomes clear. It’s a smart financial decision that enhances safety and productivity simultaneously.

Ditch the Tape, Demand Durability: Why BadAss Coatings Outlast and Outperform

When it comes to marking concrete floors in demanding warehouse and industrial environments, the choice of material is critical. While floor marking tape might seem like a quick and cheap fix, it simply can't match the longevity and performance of professionally applied coating systems like epoxy, polyurea, and polyaspartic – the BadAss standard.

The Problem with Tape on Concrete:

Standard adhesive tapes often struggle on concrete surfaces, especially in busy facilities. Here's why tape frequently falls short:

-

Poor Adhesion: Concrete is porous and can be dusty, making it difficult for adhesives to form a strong, lasting bond. Tape often peels, lifts at the edges, or bubbles, especially with temperature changes or moisture.

-

Durability Issues: Tape is susceptible to damage from forklift traffic, pallet dragging, scraping, and even heavy foot traffic. Edges fray, lines tear, and the markings quickly become worn and ineffective.

-

Safety Hazards: Peeled or frayed tape creates significant trip hazards.

-

Cleaning Difficulties: Dirt and grime get trapped under lifted edges, and aggressive cleaning methods needed in industrial settings can further damage the tape.

-

Removal Hassles: Removing old tape often leaves behind a sticky, hard-to-clean residue and can be a laborious process, sometimes requiring scraping that can mar the floor.

-

Short Lifespan: In high-traffic areas, tape may need replacement frequently, sometimes within months, leading to recurring material and labor costs and operational disruptions. Tape is often best considered a temporary solution.

The Power of Professional Coatings (Epoxy, Polyurea, Polyaspartic):

BadAss Concrete Floors utilizes high-performance coating systems specifically designed for concrete, offering superior advantages for safety striping:

-

Superior Adhesion: When applied to a properly prepared concrete surface, these coatings form a tenacious bond, either chemically reacting with or deeply penetrating the concrete substrate, preventing peeling and lifting.

-

Extreme Durability: Epoxy, polyurea, and polyaspartic coatings create a hard, resilient surface that withstands heavy forklift and pedestrian traffic, impacts, abrasion, and chemical spills far better than tape.

-

Longevity: Professionally applied coatings can last for many years, drastically reducing the need for re-striping compared to tape, offering significant long-term value.

-

Seamless Integration: Coatings become part of the floor surface, eliminating edges that can catch or trip.

-

Easy Maintenance: The smooth, non-porous surface of coated lines resists dirt and is easily cleaned with standard industrial methods.

-

Enhanced Visibility: Coatings maintain their color and clarity longer, ensuring markings remain effective. Polyaspartic topcoats offer excellent UV stability, preventing yellowing or fading in areas exposed to sunlight.

The Critical Role of Surface Preparation:

The exceptional durability of coating systems hinges on one crucial factor: meticulous surface preparation. Unlike tape, which relies solely on adhesive, coatings require a clean, sound, and properly profiled concrete substrate to achieve maximum adhesion and longevity. This typically involves:

-

Thorough Cleaning: Removing all dirt, oil, grease, existing coatings, or contaminants.

-

Mechanical Profiling: Often using diamond grinding or shot blasting to open the concrete pores and create the necessary texture (Concrete Surface Profile - CSP) for the coating to grip onto. Skipping or improperly performing this step is a primary cause of coating failure.

The Value of Certified, Professional Installation:

Achieving a durable, compliant, and long-lasting safety striping system requires more than just good materials; it demands expertise. This is where BadAss Concrete Floors excels:

-

Material Knowledge: We understand the properties and best applications for different coating chemistries (epoxy, polyurea, polyaspartic).

-

Expert Preparation: We utilize industrial-grade equipment like diamond grinders and shot blasters to achieve the optimal surface profile for maximum adhesion.

-

Precise Application: Our certified installers apply coatings according to strict manufacturer specifications, considering factors like temperature and humidity to ensure proper curing and performance.

-

Compliance Assurance: We ensure markings meet OSHA and ANSI guidelines for color, width, and placement.

-

Warranty: Professional installation often comes with manufacturer and/or installer warranties, providing peace of mind that DIY projects lack.

Ultimately, the superior performance of safety striping relies on the synergy of durable coating materials, rigorous surface preparation, and expert installation. Choosing tape is often a short-term fix leading to long-term frustration and recurring costs. Demanding durability means choosing professional coating solutions from certified experts like BadAss Concrete Floors.

Get Your BadAss Safety Striping Solution: Experience Matters

Don't settle for temporary fixes or subpar results when it comes to the safety and efficiency of your facility. Choose the proven durability and performance of professionally installed safety striping from BadAss Concrete Floors.

With millions of linear feet installed across the Southeastern US, our experience speaks for itself. We are certified installers for multiple leading coating manufacturers, ensuring we have the expertise to select and apply the optimal epoxy, polyurea, or polyaspartic system for your specific concrete floor and operational needs. We understand the critical importance of meticulous surface preparation and adhere to the highest industry standards, including OSHA and ANSI guidelines, to deliver markings that are not only compliant but built to last.

Our commitment is to provide a long-lasting, high-visibility, low-maintenance solution that enhances safety, boosts productivity, and delivers a significant return on your investment. We transform chaotic floors into controlled, efficient, and compliant workspaces.

Ready to transform your warehouse floor from chaotic to controlled? Contact BadAss Concrete Floors today at (770) 589-1605 or CLICK HERE free consultation and quote. Let's make your facility safer, more efficient, and compliant – the BadAss way.