(770) 589-1605

Sealed Concrete: Unbeatable Durability & Easy Maintenance

Why Your Concrete Deserves BadAss Protection

Concrete floors are tough, forming the foundation of countless industrial, commercial, and residential spaces. But tough doesn't mean invincible. Bare, untreated concrete is porous, like a hard sponge, making it vulnerable to a host of enemies: water damage, ugly stains from spills, chemical attack from salts or industrial fluids, and the constant wear and tear from traffic. Over time, this can lead to cracking, spalling (flaking), dusting, and a generally worn-out appearance that impacts safety, cleanliness, and the overall value of your property. Protecting this critical asset isn't just optional; it's essential for long-term performance and value.

That's where professional concrete treatments come in. Concrete sealers and concrete densifiers are the industry-standard solutions designed to protect, strengthen, enhance, and significantly extend the life of your concrete floors. These treatments transform vulnerable concrete into durable, low-maintenance surfaces ready to handle demanding environments. At BadAss Concrete Floors, we've installed millions of square feet of sealed and densified concrete. As certified installers for numerous leading manufacturers, we have the expertise to deliver floors that don't just look good, they perform exceptionally, day in and day out.

Understanding Concrete Sealers: Your Floor's Protective Shield

Think of a concrete sealer as a high-performance raincoat for your floor. It's a liquid product applied to the concrete surface designed to create a protective barrier. The primary function of any sealer is to shield the underlying concrete from damage caused by water intrusion, staining agents, chemicals, and de-icing salts. By preventing these harmful elements from penetrating the concrete, sealers play a vital role in preventing costly damage and extending the floor's service life.

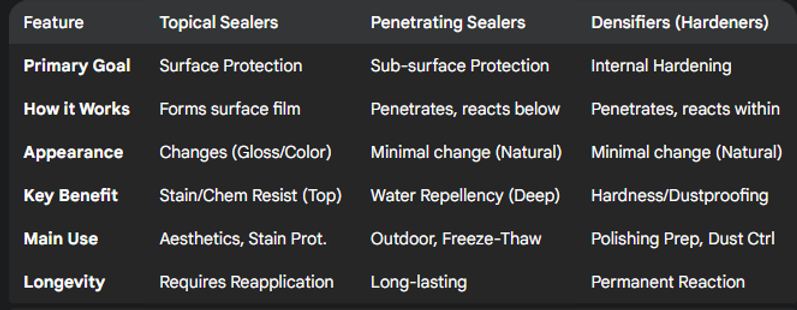

Concrete sealers fall into two main categories, each working differently and offering distinct advantages: Topical (Film-Forming) Sealers and Penetrating (Non-Film-Forming) Sealers. The best choice depends entirely on the specific needs of your environment – are you prioritizing aesthetics and stain blocking indoors, or maximum breathability and weather protection outdoors?

Topical Sealers (Surface Guardians)

How They Work: Topical sealers, also known as film-forming sealers or coatings, function exactly as the name suggests: they create a physical film or protective layer on top of the concrete surface. This layer acts like a shield, physically blocking contaminants from reaching the concrete pores. Common types include acrylics, epoxies, and polyurethanes.

Key Benefits: The primary advantage of this surface film is excellent stain and chemical resistance. Spills like oil, grease, food, or mild chemicals sit on the surface instead of soaking in, making cleanup much easier. Topical sealers are also the go-to choice for enhancing appearance. They can provide finishes ranging from a subtle satin to a high gloss, and often deepen or enrich the concrete's color, sometimes creating a desirable "wet look". This smooth, non-absorbing surface also leads to easier cleaning and maintenance.

Typical Uses: Because of their protective and aesthetic qualities, topical sealers are widely used in residential garages, basements, commercial kitchens, retail showrooms, warehouses, restaurants, and industrial facilities where appearance, spill protection, and ease of cleaning are priorities.

Limitations: Topical sealers aren't without drawbacks. Because they sit on the surface, they are subject to wear and tear from foot and vehicle traffic, abrasion, and weathering. This means they require periodic reapplication – typically every 1 to 5 years, depending heavily on the type of sealer (acrylics wear faster than epoxies or polyurethanes) and the intensity of traffic. Some glossy topical sealers can also reduce slip resistance, especially when wet, although anti-slip additives can often be incorporated. Certain types, particularly standard epoxies, can yellow or degrade with UV exposure, making them less suitable for sunny outdoor areas. Additionally, because they form a film, some topical sealers are not breathable and can trap moisture migrating up from within the concrete, potentially leading to issues like blistering or peeling if moisture levels are high.

Penetrating Sealers (Invisible Shields)

How They Work: Unlike topical sealers, penetrating sealers work below the surface. These liquids, typically based on silanes, siloxanes, or siliconates, soak into the concrete's porous network. Once inside, they chemically react with the concrete itself to form a hydrophobic (water-repelling) barrier within the capillaries. They don't create a visible film on the surface.

Key Benefits: The major advantage of penetrating sealers is that they provide protection without altering the concrete's natural appearance or texture. The concrete looks the same and retains its original slip resistance. Because they work within the pores rather than forming a surface film, they are breathable, allowing internal moisture vapor to escape. This is crucial for preventing damage from trapped moisture, especially freeze-thaw cycles in colder climates. They offer excellent protection against water absorption and the damaging effects of de-icing salts. Penetrating sealers chemically bond with the concrete, making them very durable and long-lasting – often lasting 7-10 years or more before reapplication is needed.

Typical Uses: Their characteristics make penetrating sealers the ideal choice for outdoor concrete surfaces like driveways, patios, sidewalks, pool decks, and parking structures – essentially anywhere protection from weather, freeze-thaw cycles, or de-icing salts is the primary concern, and maintaining a natural appearance and traction is important.

Limitations: While excellent for water and salt protection, penetrating sealers offer less surface stain resistance compared to film-forming topical sealers, as they don't create a physical barrier on the very top surface. They also do not enhance the concrete's appearance with gloss or color enrichment.

Understanding Concrete Densifiers: Building BadAss Strength from Within

While sealers focus on protecting concrete from the outside, concrete densifiers (often called hardeners) work to strengthen the concrete from the inside. They are chemical treatments, not coatings, that penetrate the concrete surface to significantly increase its density and hardness.

How They Work: Concrete densifiers are typically water-based liquid silicate solutions. Common types include sodium silicate, potassium silicate, and lithium silicate. When applied, the solution soaks into the concrete's pores. There, the silicates chemically react with a naturally occurring, weaker byproduct of concrete hydration called calcium hydroxide (also known as free lime). This chemical reaction transforms the soft calcium hydroxide into additional Calcium Silicate Hydrate (CSH). CSH is the primary binder in concrete – the strong, hard "glue" that gives concrete its strength. By creating more CSH within the concrete's pore structure, the densifier effectively fills voids and makes the surface matrix significantly denser, harder, and more durable.

Unlike topical sealers that form a temporary layer, this internal chemical reaction initiated by a densifier results in a permanent structural improvement to the concrete surface. The change is irreversible; the concrete itself becomes inherently stronger and denser at the surface where it matters most. This contrasts sharply with the sacrificial nature of topical coatings that wear away over time. This permanence is a core reason why densification is such a valuable long-term investment.

Key Benefits:

-

Increased Hardness & Durability: This is the primary benefit. Densified concrete exhibits a substantial improvement in surface hardness, making it much more resistant to abrasion, scratching, wear, and impact. Some tests show hardness increases of over 30% shortly after application. This makes the floor significantly tougher and extends its functional lifespan, especially under heavy forklift traffic, machinery, or constant foot traffic.

-

Dustproofing: A critical advantage, particularly in industrial settings. Untreated concrete naturally sheds fine dust particles as it wears. Densifiers eliminate this "concrete dusting" by chemically reacting with and solidifying the free lime (calcium hydroxide) that contributes to dust formation. This creates a cleaner, healthier environment and protects sensitive inventory, equipment, and processes from contamination.

-

Enhanced Concrete Polishing: Densification is often a crucial step in the concrete polishing process. By hardening and tightening the concrete surface, the densifier allows the diamond abrasives used in polishing to achieve a higher level of gloss and clarity. A densified surface holds the polish better and makes it more durable over time. On softer concrete, densification is often necessary to prevent the aggregate from being pulled out during grinding, ensuring a smooth, high-quality polish. The synergy between densification and polishing results in a floor that is not only beautiful but exceptionally hard and long-lasting.

-

Reduced Porosity / Increased Density: Filling the concrete's pores makes the surface less permeable. This increased density contributes to improved stain resistance (though not as much as a topical sealer) and overall longevity by restricting the ingress of water and other potentially harmful substances.

Sealer vs. Densifier: What's the Difference and Do I Need Both?

It's crucial to understand the distinct roles of these two treatments. Let's recap the core difference:

-

Concrete Sealers: Primarily act as a protective barrier against external elements like water, stains, and chemicals. They work either on the surface (topical) or just below it (penetrating). Think of them as the floor's shield.

-

Concrete Densifiers: Work internally through a chemical reaction to improve the concrete's fundamental properties, increasing its hardness, density, and abrasion resistance. Think of them as strengthening the concrete's core structure.

So, are they mutually exclusive? Absolutely not. In many situations, particularly in demanding environments or when aiming for the highest level of performance and longevity, sealers and densifiers are used together as part of a comprehensive floor treatment system.

This combined approach represents a layered defense strategy for your concrete. The densifier provides the foundational strength, hardening the surface and reducing dusting, making the concrete inherently more robust. Then, a sealer is applied to add targeted protection against specific threats that the densifier alone might not fully address, such as aggressive chemical spills or deep-staining liquids, or to achieve a desired aesthetic like high gloss. For polished concrete, densification is often followed by a specialized guard product (a type of sealer) to maximize stain resistance and maintain the shine. This multi-faceted approach addresses different potential failure points, creating a floor system that offers maximum protection and performance.

The Payoff: Benefits of Professionally Sealed & Densified Concrete

Investing in professionally applied concrete sealers and/or densifiers delivers a powerful combination of benefits that protect your concrete and enhance your space:

-

Unmatched Durability & Extended Lifespan: Treated concrete stands up far better to the rigors of daily use. Increased hardness and abrasion resistance from densifiers, combined with the protective barrier of sealers, means your floor resists wear, impact, and heavy traffic, significantly extending its service life compared to untreated concrete.

-

Superior Protection: This is the core function. Sealers and densifiers work together or individually to guard against a wide range of threats:

-

Water & Moisture: Preventing absorption protects against freeze-thaw damage (cracking, spalling) in cold climates and inhibits mold/mildew growth in damp areas.

-

Stains: Topical sealers provide excellent resistance to spills like oil, grease, food, beverages, and many common chemicals, keeping floors looking clean. Densifiers also contribute by reducing porosity.

-

Chemicals & Salts: Sealers (especially epoxies, polyurethanes) create a barrier against harsh chemicals and damaging de-icing salts.

-

-

Simplified Maintenance: Sealed and densified concrete is significantly easier to maintain. The smooth, non-porous (or less porous) surface prevents dirt, grime, and spills from penetrating, making cleaning faster and easier. Often, only routine sweeping and occasional mopping with mild cleaners are needed. There's no need for the laborious waxing or stripping required by some other flooring types.

-

Improved Safety & Hygiene:

-

Dust Elimination: Densifiers permanently stop concrete dusting, improving air quality and protecting equipment.

-

Slip Resistance: While some glossy sealers can be slippery, penetrating sealers maintain natural texture, and anti-slip additives can be incorporated into topical sealers to enhance traction, especially in wet areas. Polished concrete, often achieved with densifiers, typically meets or exceeds OSHA standards for slip resistance.

-

Hygiene: The seamless, non-porous nature of sealed or densified/polished concrete inhibits the growth of bacteria, mold, and mildew, making it an excellent choice for environments where cleanliness is critical.

-

-

Enhanced Aesthetics: Treatments can dramatically improve the look of concrete. Topical sealers offer a range of finishes from matte to high gloss, and can enhance or change color. Densifiers are key to achieving a deep, durable, high-gloss polished concrete finish. The improved light reflectivity of sealed or polished floors can also brighten spaces, potentially reducing lighting costs.

Real-World Applications: Where BadAss Floors Make the Difference

The benefits of sealed and densified concrete translate across a wide range of industries and applications:

-

Industrial & Warehouses: These environments face extreme demands: constant forklift traffic, heavy loads, potential impacts, chemical exposure, and the critical need for dust control. Densifiers are essential here, providing exceptional abrasion resistance to withstand relentless traffic and eliminating concrete dust that can damage goods, interfere with processes, and harm sensitive equipment like forklifts and HVAC systems. Topical sealers like heavy-duty epoxies or urethanes add a crucial layer of chemical resistance against spills and make floors much easier and faster to clean, improving operational efficiency. The smooth, durable surface also reduces wear and tear on forklift tires and allows for more efficient movement.

-

Commercial & Retail (Stores, Restaurants, Showrooms): Appearance, durability, and ease of maintenance are key in these public-facing spaces. Topical sealers (epoxies, polyurethanes, polyaspartics) shine here, offering high resistance to foot traffic, spills (food, drinks, cleaning products), and stains while providing customizable aesthetics – gloss levels, colors, even decorative flakes or metallic effects – to match branding and create an inviting atmosphere. Densified and polished concrete is also an excellent choice, offering extreme durability for high-traffic zones, a modern aesthetic, and very low maintenance requirements.

-

Residential (Garages, Patios, Driveways, Basements): Homeowners benefit greatly from protecting their concrete. Sealers guard garage floors against oil drips, gasoline spills, hot tire pickup, and road salts tracked in during winter. For outdoor patios and driveways, penetrating sealers are ideal, offering invisible protection against water absorption and damaging freeze-thaw cycles without making surfaces slippery. In basements, sealers prevent moisture issues and mold growth, while densifiers can eliminate annoying concrete dust. Topical sealers also allow homeowners to upgrade the look of these functional spaces.

-

Institutional (Schools, Hospitals, Civic Centers): These facilities require flooring that is incredibly durable, safe, hygienic, and easy to maintain on tight budgets. Sealed and/or densified/polished concrete excels in these demanding environments. They offer outstanding resistance to heavy foot traffic, rolling equipment, and frequent cleaning protocols. The seamless nature of these finishes eliminates grout lines where bacteria can hide, promoting better hygiene. Low maintenance needs free up staff time and reduce the use of harsh cleaning chemicals.

The Long-Term Value: How Sealed & Densified Concrete Saves You Money

Treating your concrete with professional sealers and densifiers isn't just an expense; it's a strategic investment that delivers significant long-term cost savings. By protecting and enhancing your concrete from the start, you avoid much larger costs down the road. Here's how:

-

Reduced Maintenance Costs: This is one of the most immediate and significant savings. Sealed and densified surfaces are non-porous or significantly less porous, preventing dirt, spills, and grime from penetrating. Cleaning becomes much faster and requires less labor and fewer, milder cleaning chemicals. Unlike surfaces like VCT, there's no need for costly and time-consuming waxing, stripping, or buffing. Some studies suggest annual maintenance savings for polished/densified concrete can be substantial compared to traditional flooring.

-

Prevention of Costly Repairs: Untreated concrete is susceptible to damage that requires expensive intervention. Sealers and densifiers prevent or minimize:

-

Staining: Blocking oil, chemicals, and other liquids prevents deep-set stains that are difficult or impossible to remove.

-

Chemical Attack: Protective sealers prevent acids, salts, and other corrosive substances from etching or degrading the concrete surface.

-

Water Damage & Freeze-Thaw: Sealers (especially penetrating ones) block water absorption, preventing cracking, spalling, and deterioration caused by freeze-thaw cycles in colder climates.

-

Impact & Abrasion Damage: Densifiers significantly harden the surface, reducing chipping, scratching, and wear from traffic and impacts. Avoiding these issues eliminates the need for patching, grinding, overlays, or even complete slab replacement.

-

-

Extended Concrete Lifespan: By protecting the concrete from its enemies and improving its inherent properties, sealers and densifiers significantly extend the functional service life of the concrete slab itself. This delays the massive expense and disruption associated with major concrete renovation or replacement.

-

Reduced Dust-Related Costs (Industrial/Warehouse): Concrete dust isn't just a nuisance; it's costly. Densifiers eliminate dusting. This translates directly to savings by:

-

Lowering Cleaning Labor: Less time spent constantly sweeping or vacuuming fine dust.

-

Protecting Inventory: Prevents dust from settling on and contaminating products or raw materials.

-

Reducing Equipment Damage: Dust is abrasive and harmful to moving parts in forklifts, conveyors, HVAC systems, and other sensitive machinery, leading to increased maintenance and premature failure. Dustproofing protects this expensive equipment.

-

-

Operational Efficiencies: Beyond direct repair and maintenance savings, treated floors can improve operations. The enhanced light reflectivity of sealed or polished floors can reduce the need for artificial lighting, saving energy costs. Smoother, harder surfaces can also improve the efficiency and reduce wear on material handling equipment like forklifts.

The BadAss Difference: Why Professional Application is Non-Negotiable

Achieving the full benefits and longevity of concrete sealers and densifiers isn't just about choosing the right product; it's about flawless execution. This is where professional application by certified experts like BadAss Concrete Floors makes all the difference.

The Critical Role of Surface Preparation: Industry experts agree: proper surface preparation is arguably the most critical step for the success of any concrete sealer or densifier application. Without it, even the best products will fail prematurely. Preparation isn't just a quick sweep. It involves:

-

Thorough Cleaning: Removing all contaminants like dirt, dust, oil, grease, curing compounds, or previous coatings that could interfere with adhesion or penetration.

-

Concrete Repair: Identifying and properly repairing existing cracks, spalls, or other surface defects.

-

Achieving the Right Profile: Mechanically preparing the surface (often through diamond grinding or shot blasting) to achieve the specific Concrete Surface Profile (CSP) recommended by the product manufacturer. The CSP refers to the concrete's roughness, which is crucial for ensuring the sealer or densifier can properly bond or penetrate. Professionals adhere to industry standards like those set by the International Concrete Repair Institute (ICRI) for CSP.

Expert Application Matters: Applying these products correctly requires skill and the right tools. Professionals like BadAss Concrete Floors possess:

-

Knowledge & Experience: Understanding how different products behave under various conditions (temperature, humidity) and how to apply them evenly at the correct thickness or coverage rate.

-

Specialized Equipment: Utilizing industrial-grade equipment like diamond grinders, shot blasters, and professional sprayers ensures proper preparation and application that DIY methods simply cannot replicate.

-

Avoiding Pitfalls: Professionals know how to avoid common DIY mistakes like inadequate prep leading to peeling or delamination, uneven application causing aesthetic issues, or trapping moisture leading to bubbles or blisters. A failed DIY job often costs more in the long run when professional remediation is required.

The Value of Certification & Warranties: BadAss Concrete Floors employs certified installers. This isn't just a title; it signifies recognized expertise and adherence to best practices. Crucially:

-

Manufacturer Requirements: Many high-performance sealer and densifier manufacturers require their products to be installed by trained or certified applicators following specific protocols to ensure proper performance.

-

Warranty Protection: Applying products yourself or using non-certified installers often voids the manufacturer's product warranty. Professional installation by a certified team like ours ensures that the manufacturer's warranty remains valid, protecting your investment.

Ultimately, hiring a certified professional is the only reliable way to guarantee that you achieve the full durability, longevity, and performance potential promised by quality sealers and densifiers, while also securing the peace of mind that comes with a valid manufacturer warranty. It transforms the application from a risky gamble into a secure investment.

Conclusion: Get BadAss Floors That Last

Professionally sealed and/or densified concrete isn't just a floor treatment; it's a smart strategy for maximizing the value, performance, and lifespan of your concrete surfaces. It delivers a powerful combination of benefits: rugged durability against traffic and wear, robust protection from stains and damage, simplified cleaning and maintenance, enhanced safety and hygiene, improved appearance, and significant long-term cost savings.

At BadAss Concrete Floors, our extensive experience, industry certifications, and commitment to using high-quality products and meticulous preparation ensure you get results that not only meet but exceed expectations. We understand the science behind these treatments and how to apply them for maximum effectiveness in your specific environment.

Ready for concrete floors that look great, perform flawlessly, and save you money over time? Get BadAss results.

Don't settle for less. Demand BadAss Concrete Floors. Call us today at (770) 589-1605 or CLICK HERE to request your free, no-hassle quote!